Introduction to ice trays for cube ice machines and the advantages of ice trays for ICEMA cube ice machines

As one of the most popular edible ices, cube ice has a growing market share. The machines that produce cube ice are divided into commercial cube ice machines and industrial cube ice machines according to the use site and ice production output.

Industrial Cube Ice Machine

Commercial Cube Ice Machine

As an edible cube ice machine, the ice tray that is in direct contact with the ice is particularly important. Both the material and quality of the ice tray are related to the user's safety.

In recent years, some businesses have developed aluminum ice trays to reduce costs. The material is die-cast aluminum. Since this type of ice tray is a newly developed product, it is difficult to control the quality, resulting in uneven ice formation, unsmooth ice removal and many other problems. At the same time, the aluminum used is difficult to meet food grade standards, so aluminum ice trays should be avoided as much as possible when selecting equipment.

Aluminum ice tray

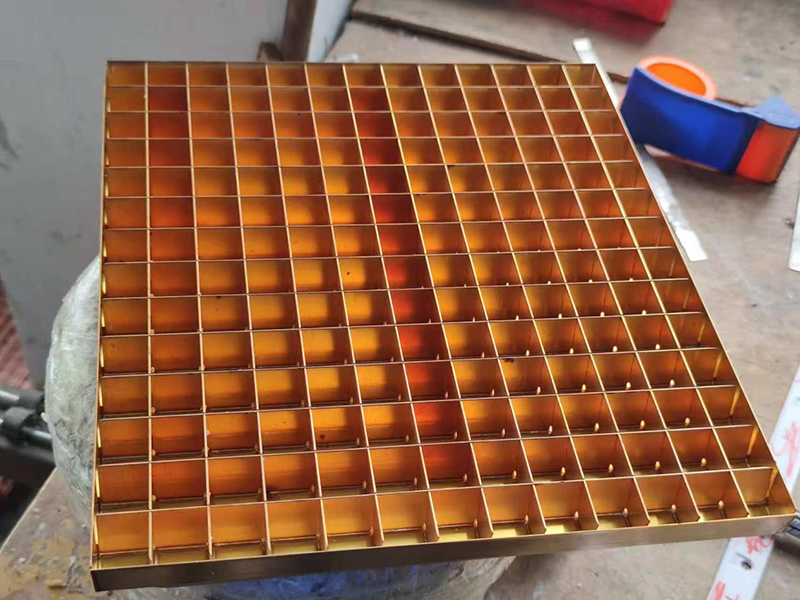

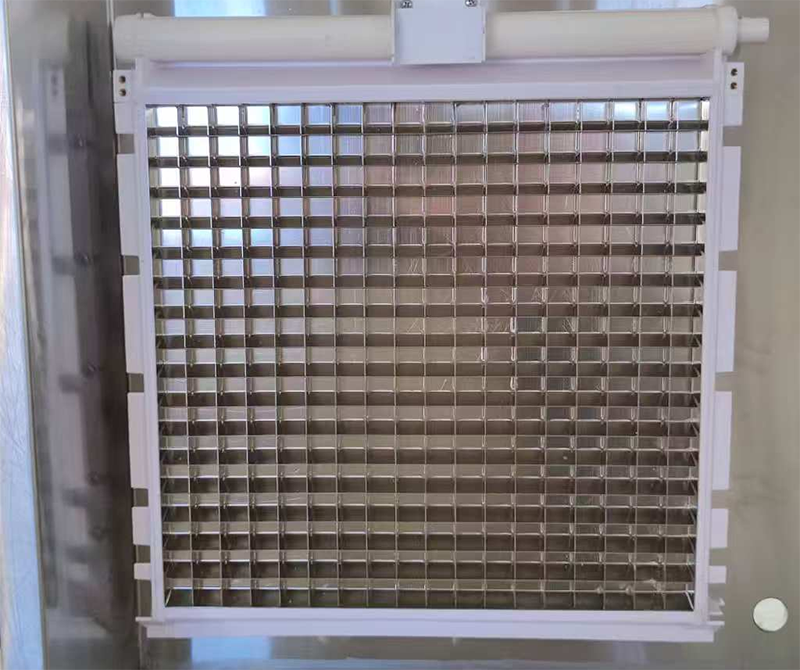

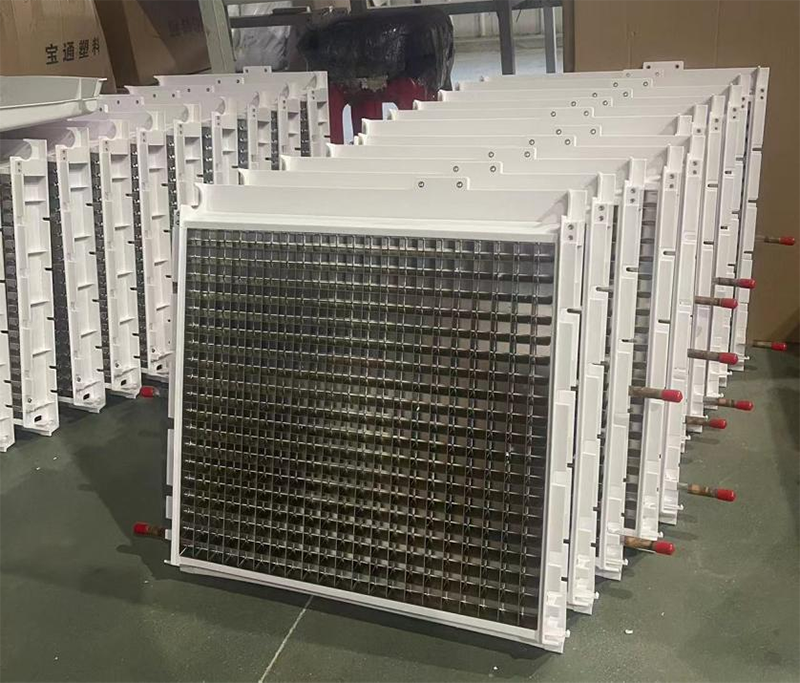

All ice trays used in Icema's cube ice machines are made of copper. They are made of copper sheets, which are crisscrossed to form squares of equal size grids. Welding paste is applied between the copper sheets. The assembled ice tray is placed in a 200-degree Celsius oven for baking. The welding paste melts at high temperature and penetrates into the gaps between the copper sheets. After the entire ice tray cools, the copper sheets are firmly connected to each other. The welded ice tray is sent to the nickel plating workshop for overall nickel plating. The nickel plating process must be carried out strictly in accordance with food grade requirements. After the nickel plating is completed, white plastic parts are installed, and a finished ice tray is ready.

Copper sheet

Assemble the ice tray

Assemble the ice tray(2)

Finished ice tray

Since the height of the copper sheet is 22mm, and the size of the ice tray with the highest ice-making efficiency is 22×22×22mm, the ice trays of the standard model of ICEMA’s ice cube machines all use ice trays of the above specifications, with 19 grids horizontally and 21 grids vertically. One ice tray can produce 399 ice cubes at a time, which is more than some machines that use 18 grids horizontally and 19 grids vertically, and only 342 ice cubes in one ice tray, 57 more. If it is a 5-ton ice machine, according to ICEMA's design of using 18 ice trays, each time the ice is removed, the ICEMA ice cube machine will produce 57 grids × 18 = 1026 more ice cubes than ordinary ice cube machines. Calculated based on the weight of 9g per ice cube, the ICEMA ice cube machine will produce 9234g more than ordinary ice cube machines. This is why the ICEMA ice cube machine has overproduction.

Finished ice tray

It should be noted that some merchants in the market claim that the ice tray is made of stainless steel, but it is not. Since the process has certain requirements on the material, stainless steel cannot be used to make such an ice tray. However, copper is a real food grade material, so there is no need to deliberately say that it is stainless steel.

22*22 ice tray

35*35 ice tray

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BE

BE

BN

BN

EO

EO

JW

JW

LA

LA

MN

MN

MY

MY

UZ

UZ

GD

GD